Building Rock-Solid BOPIS: A Guide to Click-and-Collect Commerce

Written by

Broadleaf Commerce

Published on

Sep 25, 2025

eCommerce keeps throwing curveballs, but few trends have stuck around like Buy Online, Pick Up In-Store (BOPIS). What became a pandemic-era necessity is now table stakes for any serious retailer. If you've been tasked with building or improving a BOPIS solution, you know it's way more complex than just slapping a "pickup" option on your checkout page.

BOPIS consistently presents itself as both a huge opportunity and a massive technical challenge. With the right architectural approach and platform, it doesn't have to be a nightmare to implement.

Why BOPIS Actually Matters (Beyond the Obvious)

Sure, everyone talks about how BOPIS saves customers shipping costs and gets them their stuff faster. But here's what really makes retailers love it: it drives serious foot traffic. A significant percentage of BOPIS customers make additional purchases during pickup. That's found money.

From a technical standpoint, a well-executed BOPIS strategy eliminates some of the biggest pain points in eCommerce logistics: failed deliveries, package theft, and those dreaded last-mile costs that eat into margins. To pull this off successfully, your backend needs to be bulletproof.

The Real Technical Challenges

Let me be honest about what you're signing up for. BOPIS is more than just inventory management (though that's critical). You're building a bridge between two completely different operational systems: your eCommerce platform and your physical stores. These systems often speak different languages, run on different schedules, and have very different ideas about what "available inventory" means.

The biggest gotcha? Inventory accuracy. An item might be marked as in stock online, but in the physical store, it could be damaged, misplaced, or already set aside for another order. Safety stock becomes vital here - a buffer of inventory held to mitigate the risk of stock-outs due to these inaccuracies or unexpected demand. For BOPIS, retailers can implement a safety stock rule that only allows an item to be sold online for in-store pickup if the system shows more than a certain quantity on hand. A common practice is setting a safety stock threshold of 2-3 units before an item becomes available for online purchase and in-store pickup. This prevents the disappointment of a failed pickup.

Breaking Down the Architecture with Broadleaf

Building a solid BOPIS system with Broadleaf Commerce requires understanding several key components:

Inventory: The Make-or-Break Component

Real-time inventory sounds simple until you try to implement it across multiple locations. You need to track not just "how many do we have," but "how many can we actually sell right now." This requires accounting for safety stock, items already pulled for other orders, and the time it takes staff to locate items in-store.

Broadleaf's InventoryServices are a key integration point, allowing Cart Operations to make API calls for real-time checks and reservations. The InventoryServices can handle special cases like serialized inventory, which tracks individual units with unique identifiers. The FulfillmentPricingProvider is a separate component that integrates with other services to provide shipping rates and labels.

The reservation process is crucial. When a customer places a BOPIS order, Broadleaf's InventoryServices immediately creates a "soft" inventory reservation for those items. This temporarily holds the stock until checkout is completed. After successful checkout, this converts to a "hard" reservation, effectively decrementing the available inventory. No more customers arriving to find their item was sold to someone else.

Can't fulfill the entire order from one location? Broadleaf's cart and fulfillment systems can split the order. The system proposes to the customer that some items be picked up at one store, while others are shipped or picked up elsewhere. The fulfillment pricing and calculation services handle this and can be extended with custom order splitting logic.

Fulfillment: More Complex Than You'd Think

A simple "free pickup" option works fine until you deal with edge cases. What about oversized items that require special handling? Products that need to be transferred from the back warehouse to the pickup location? Or partial fulfillment, where a customer orders multiple items, but only some are ready for pickup?

Broadleaf's FulfillmentCalculator system handles these scenarios through flexible configuration. Each calculator can apply to specific origins, destinations, and other criteria. For basic in-store pickup, you set up a fixed-rate calculator (at $0) tied to specific FulfillmentOrigin locations. The FulfillmentDestination can match a specific local geographic area, ensuring the option is only available to nearby customers.

The real power lies in extensibility. You can build a custom FulfillmentPricingProvider that calculates pricing and options based on unique business rules, like an item's size or handling requirements. Large items could be routed to stores with loading docks, while standard items could be picked up anywhere.

The WeightCalculationService automatically handles unit conversions and aggregations for packages with multiple units of measurement. Critical for scenarios where customers order a mix of heavy and light items, as the system can suggest the best fulfillment location based on weight.

System Integration and Data Flow

Successfully implementing BOPIS requires robust system integration. Broadleaf's composable architecture means its microservices can be deployed separately or together, and each service exposes REST APIs that other systems can consume. You can integrate with various internal systems like a Warehouse Management System (WMS) or Point-of-Sale (POS) system.

Three primary ways to manage data synchronization for BOPIS:

- Real-time API Calls: The most direct method. Your frontend makes an API call to a Broadleaf endpoint, which orchestrates a chain of API calls to other services like the Inventory Service and Fulfillment Service. Provides the most up-to-the-minute data.

- Nightly Batch or Periodic Updates: Synchronizes data at scheduled intervals. Inventory levels and product data that don't need real-time updates can be synchronized via a batch process. Broadleaf includes functionality for scheduled jobs to automate recurring tasks.

- The Import Module: Broadleaf's robust import module allows bulk data updates for various use cases:

- Mass updates to product details (changing sale prices across entire categories)

- Integrating data from third-party management tools, such as PIM systems or Excel spreadsheets, with inventory data

- Migrating data from legacy systems

- Supports multiple formats, pre-configured templates, and detailed error logs for validation

When deciding between real-time API calls and batch processing, weigh performance and scalability.

Real-time API calls are essential for mission-critical, time-sensitive data like inventory checks during checkout. They ensure the highest accuracy and smooth customer experience. Over-reliance on synchronous, real-time calls across services can introduce latency and create bottlenecks if not handled properly.

Batch processing is highly scalable and efficient for large volumes of data that don't require instant updates. Updating thousands of product descriptions, promotional text, or category assets is far more efficient in a single batch job than through thousands of individual API calls. This offloads non-critical work from the transactional path, allowing your system to handle high-volume checkout traffic without being bogged down by unnecessary data synchronization.

Common BOPIS Scenarios in Broadleaf

Pricing Differences: What happens if the online price and the in-store price for an item differ? Broadleaf's pricing architecture allows for a single source of truth. For a BOPIS order, the price is determined at checkout in the cart service, drawing from either the Catalog or an external Pricing Service. The in-store price isn't a factor at that point. If a store wants to honor a different price at pickup, the order total would need adjustment at the POS system, managed outside the platform's standard checkout flow.

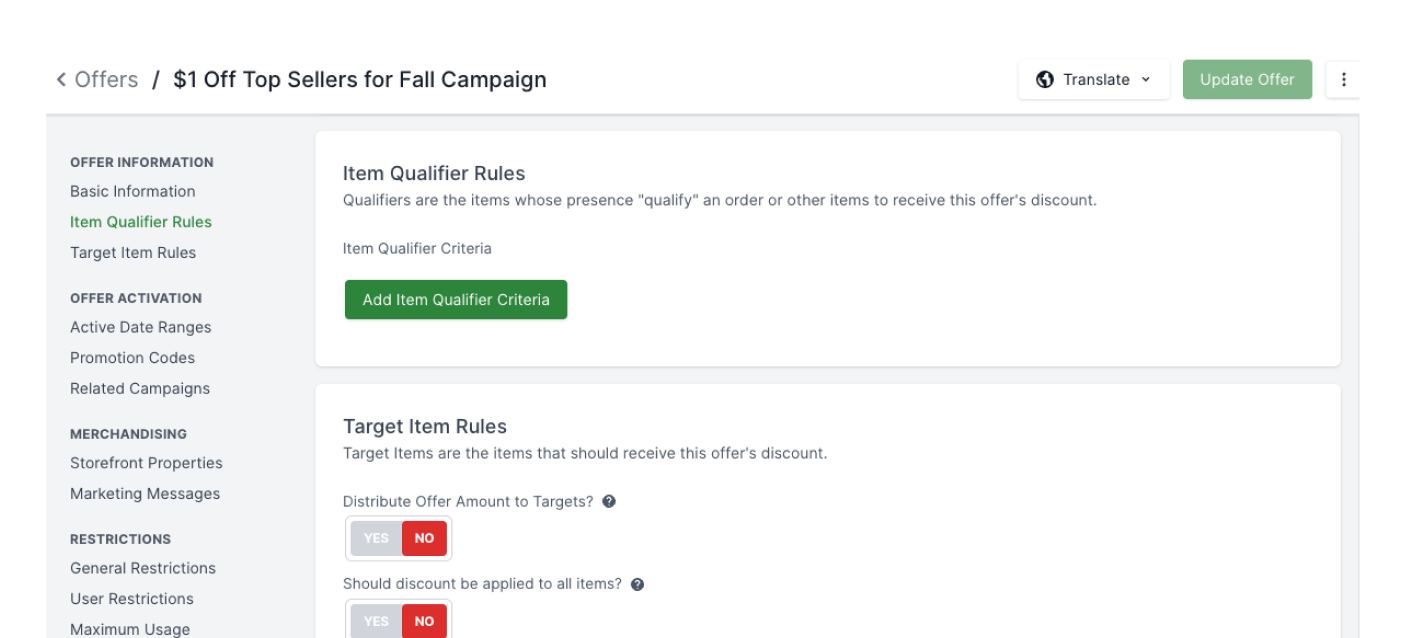

Offers and Promotions: Broadleaf gives you granular control over how offers and promotions are applied. The system uses an "intuitive, best offer wins by default" approach. Discounts are applied in the cart at purchase time, regardless of whether it's for shipment or pickup. The system also supports offers for specific customer segments, making it possible to create promotions exclusively for BOPIS customers.

In-Store Returns: Can a BOPIS order be returned to a store? Broadleaf supports this via the Order Services module, which includes an API for Returns and Cancellations (RMA). While the specific workflow would need retailer implementation, the underlying system has the necessary components to facilitate in-store returns for orders placed online.

The Bottom Line

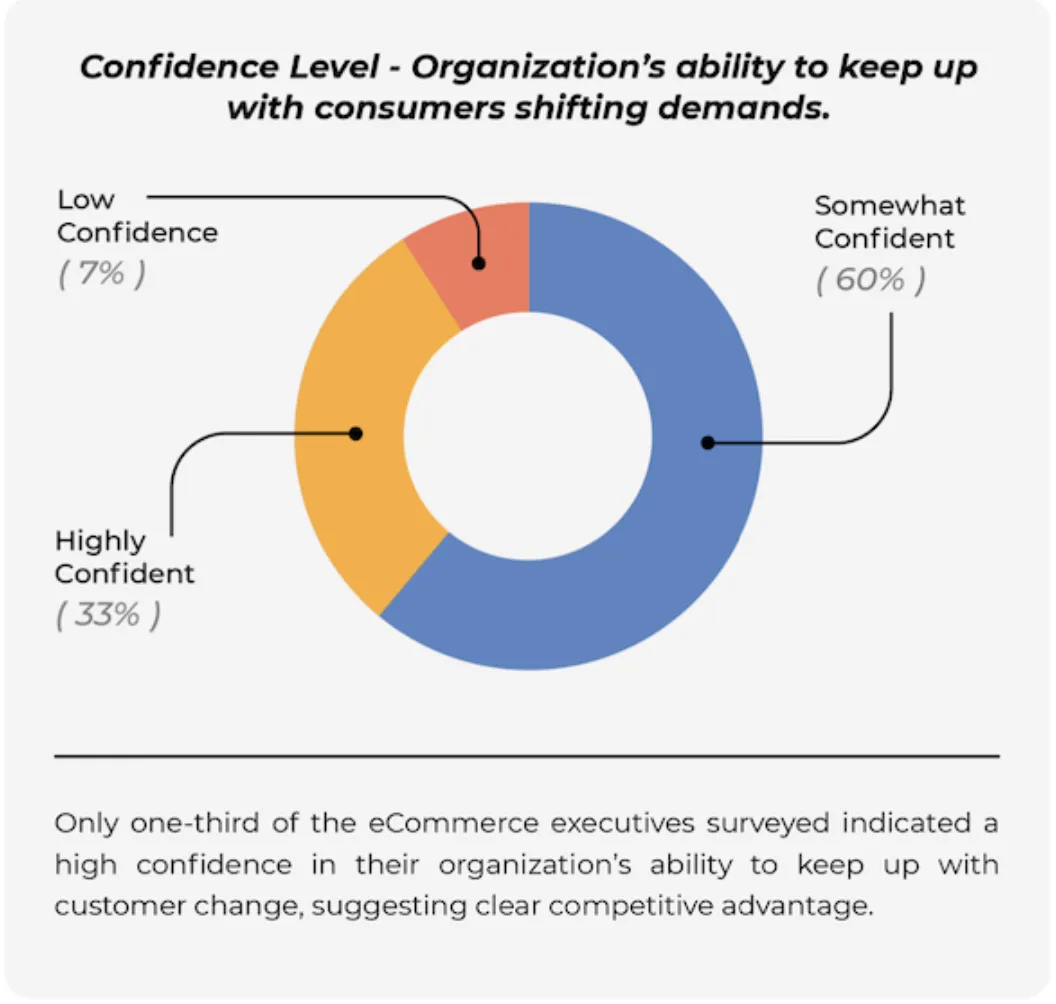

BOPIS isn't going anywhere. Customer expectations around pickup speed and convenience are only increasing. The retailers who nail this will have a significant competitive advantage in both customer satisfaction and operational efficiency.

Build with flexibility in mind from day one. Your BOPIS requirements will evolve as your business grows and customer behaviors change. A composable platform like Broadleaf gives you the architectural foundation to adapt without starting from scratch every time.

The technology is only half the battle. You'll also need tight coordination between your development team, operations staff, and store personnel. But when it all comes together, BOPIS can transform both your customer experience and your bottom line.